Written by: Adam Jackson

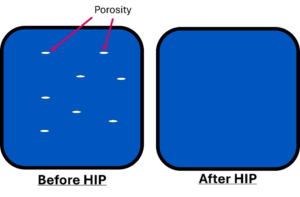

Hot Isostatic Pressing (HIPping) is an advanced manufacturing technique that is useful for the manufacturing of components from metal powders or metal 3D printing, such that tiny gaps in the metal can be removed, like how you would squeeze the air bubbles out of clay.

This is achieved through a combination of heating the part until its nearly at its melting point, and applying very high pressure all over the part, often as high as 2000x that of the air we breathe. This closes all the tiny gaps in the part, making the metal denser, stronger and longer lasting.

Although not a well-known manufacturing technique, most people will interact with components that been HIPped at various points in their life.

Jet engines spin at 1,000’s of revolution per minute, and get very hot! HIPping of the turbine blades makes them stronger, more reliable, and able to handle the high temperatures better.

Hot Isostatic Pressing is used to manufacture components for all sorts of aspects in electricity production. From the nuclear fuel cladding for nuclear fission to the Diffusion Bonding of different materials for nuclear fusion research, the nuclear industry is heavily reliant on HIPping. Nuclear material scientist are currently developing the world’s largest HIP, at a cost of £1,000,000’s.

Many of us will know someone who will be unfortunate enough to require a knee/hip replacement later in life. When first introduced in the 1970’s, these artificial joints were only able to last about a decade, meaning a person would need to have them replaced multiple times in their life. However, modern artificial joints are able to last as long as 25 years thanks to improvement in materials and HIPping.

Hot Isostatic Pressing is a high-cost technique so is reserved for high performance vehicles. Many components in F1 cars and other hyper cars are 3D printed to save weight, and these components need to be HIPped to remove porosity and improve the lifespan. Examples include gears for the gearbox, and other high performance engine components.

As you can see, the applications for Hot Isostatic Pressing extend far and wide. It’s uses extend from how our electricity is produced to how we go on holiday, the motorsport we watch and for some people, even inside the body. HIPping plays a quiet but important role in keeping the world turning!