Written by: Phoebe May

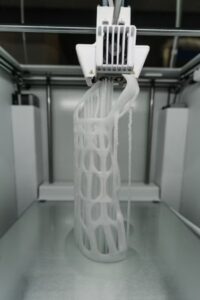

Additive manufacturing (AM), sometimes referred to as 3D printing, is a way of making objects by adding material layer by layer. It is like drawing with a 3D pen except instead of ink, it can use plastic, metal, or ceramic.

AM is useful because it allows for customisation, intricate designs, quicker production and less material waste. This is because AM builds objects that are very close to the desired final shape (also known as ‘near net shape’), unlike traditional manufacturing, which often involves cutting away extra material.

Lots of industries rely on and use AM:

AM is great but it does have some drawbacks:

AM is improving every day with scientists working on printing human organs, entire houses, and even tools for astronauts in space. As technology advances, we might soon be able to print anything we need, whenever we need it. So, whether you are thinking of building a rocket or printing a custom phone case, additive manufacturing is shaping the future, one layer at a time!

Check out our video about additive manufacturing (this will open YouTube).