Written by: Harry Craven

Have you ever mixed ingredients together in the kitchen and wondered if it would turn out right before putting it in the oven? Computational materials modelling lets scientists do exactly that with materials, running tests on computers to see how different mixtures and designs will perform before making anything in the real world.

Computational materials modelling is the science of using powerful computers to predict how materials will behave before anyone makes them in a laboratory. Instead of spending years mixing different metals together and testing them one by one, scientists can run simulations on a computer to find the best combinations. This saves large amounts of time and money because researchers can test thousands of possibilities before conducting expensive real-world experiments.

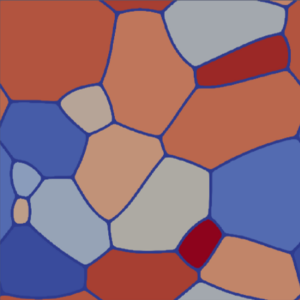

These computational models can be designed for different length scales depending on what you need to understand. At the smallest scale, we can track individual atoms and how they bond together, but this becomes very slow when simulating larger pieces of material. For many engineering problems, scientists use mesoscale modelling, where the models track larger features like the structures that form inside materials. One powerful mesoscale approach is called phase field modelling, which simulates how different structures (called phases) grow and compete inside materials as they form.

One of the most important tools is thermodynamics, the science of energy and how it moves through systems. Every material wants to minimise its energy, like how water flows downhill. When you mix different materials and heat them up, thermodynamics helps to predict which combinations will be stable. Scientists use thermodynamic data like a recipe book that tells the computer which combinations are possible at different temperatures, allowing us to predict what happens when we heat, cool, or mix materials together.

One critical application is optimising materials for extreme environments. Turbine blades in jet engines spin at incredible speeds while being blasted by gases hotter than 1000°C. Their strength depends on their microstructure and how the metals inside them interact. Through computational modelling, engineers can simulate how different metal mixtures can affect the blades’ structure, predicting which combinations produce the strongest, most heat-resistant blades before manufacturing expensive prototypes.

The range of metal mixtures is not the only factor affecting the strength of these blades; the rate at which the metals cool during casting in factories can have a significant impact as well. If these metal alloys cool unevenly, any defects in the structure can create weak spots. Models focused on solidification allow engineers to identify where these problems occur and design the casting process to avoid these.

As computers become faster, scientists can create more advanced, precise models that capture more real-life features of materials. They are using these models to create stronger alloys for aircraft that use less fuel, materials that can withstand the extreme conditions in space and much more!